Cosmetic Processing

Liquid soap and shampoo

Overview

Overview

Liquid soaps and shampoos come in various viscosities, ranging from thin and watery to thick and creamy formulations, so the equipment for their production must be adaptable to handle different viscosity levels. It is necessary to ensure very high yields of production, repeatability, and minimal cleaning resources consumption.

Also, achieving and maintaining a stable emulsion is critical to ensure that oil and water-based ingredients remain uniformly mixed, and some formulations may require precise temperature control during production, especially during heating and cooling stages.

Another critical aspect is that liquid soaps and shampoos often contain fragrances and colorants that must remain stable throughout the production process, plus maintaining strict hygiene standards is essential, so the equipment must be designed for easy cleaning and sanitization to prevent contamination and ensure product safety.

Lastly, these products must adhere to industry regulations and standards, such as Good Manufacturing Practices (GMP), FDA guidelines, and specific cosmetic and personal care product regulations.

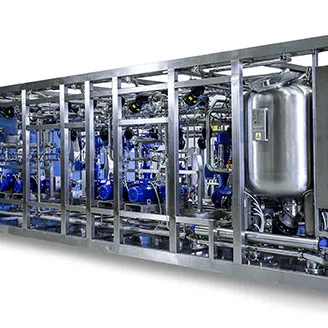

Olsa can supply customized plants for a wide range of different liquid soaps and shampoos production, with in-line instrumentation for process control, automatic in-line raw material loading and foam control. This configuration can lead to significant reduction in production cycles and water consumption.

Vacuum mixers homogenizers, preparation vessels, CIP/SIP skids and TCUs are usually part of the systems for these applications. As production volumes may vary, equipment is scalable to accommodate both small-scale and large-scale production requirements.

Efficient equipment design minimizes energy consumption, reducing operational costs and environmental impact.

Thanks to the synergy with MGA (Masco Group Automation), Olsa can provide an automation package to guarantee process control and related reporting.

Other Cosmetic processing applications