Biopharma processing

Blood plasma fractionation

Overview

Overview

Blood plasma fractionation is a complex and precise process that separates blood plasma into its individual components, mainly proteins, including clotting factor, albumin, immunoglobulins and fibrinogens, enzymes, and antibodies with incredible therapeutic value. These plasma-derived products are used to treat a variety of medical conditions, including immune disorders, hemophilia, and neurological diseases.

Within this process, thawing is the first step, necessary for frozen blood that, stored at ultra-low temperatures, needs to return to its liquid state. This step is also the most critical one: the challenge is to ensure a fast and continuous thawing rate without stressing the product, especially from temperature perspective.

Proper thawing methods and protocols are essential to maintain the integrity of raw material and ultimately the safety, potency, and efficacy of plasma-derived products. By adhering to industry standards and best practices, blood fractionation facilities can ensure that the therapeutic products they produce are of the highest quality and can positively impact the lives of patients.

After collecting plasma in liquid form, fractionation occurs and consists of a progressive addition of ethanol to cause proteins precipitation; proteins collection occurs through centrifugation.

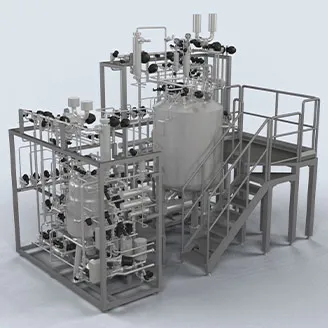

Thanks to years of experience in the field, Olsa has developed a cutting-edge and high-performance thawing tank, the ThawMX®. This proprietary technology has the impressive capability to achieve a thawing rate twice as fast as traditional thawing systems and many other advantages.

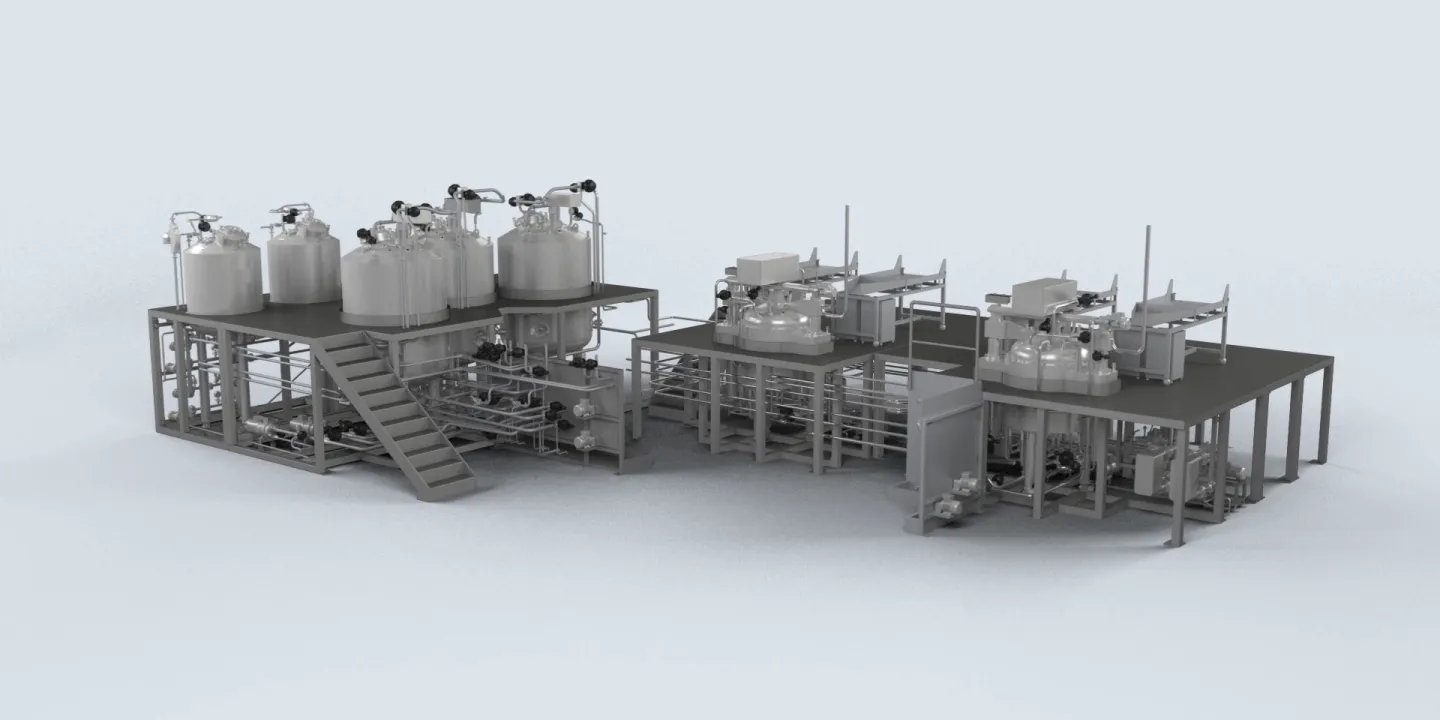

Moreover, Olsa makes sure the whole thawing process is designed to ensure maximum efficiency and safety.

Transfer Panels are widely used in the process to manage the intermediate batches and their transfer to subsequent process stages; they also facilitate the cleaning-in-place of vessels and pipelines through CIP units installed in the system.

Temperature Control Units (TCUs) are also integral to the blood fractionation process to ensure the safety, efficacy, and quality of blood components, minimize the risk of adverse events, and comply with regulatory requirements.

Thanks to the synergy with MGA (Masco Group Automation), Olsa can provide a high-level automation package (for example SCADA, DCS) able to handle receipts to guarantee process control and reporting according with highest pharmaceutical and biopharmaceutical standards.

Other Biopharma processing applications