Biopharma processing

Thawing

Overview

Overview

Plasma for fractionation, the raw material for PDMPs, is considered a strategic resource for the pharmaceutical and biotech industry, and PDMPs are listed by the World Health Organization as essential medicines.

The proteins derived from the process, such as immunoglobulins, albumin, clotting factors, gamma globulins, are used to produce medicines to treat several chronic and acute life-threatening diseases. However, blood plasma fractionation is a difficult process, which has to consider safety as well as efficiency, since it involves treating human blood, a precious and delicate resource.

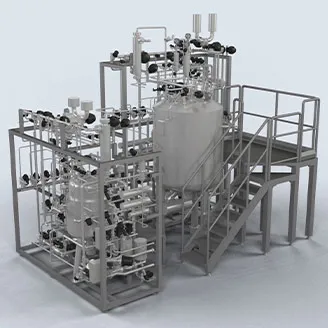

Within the fractionation process, the most crucial step is plasma thawing.

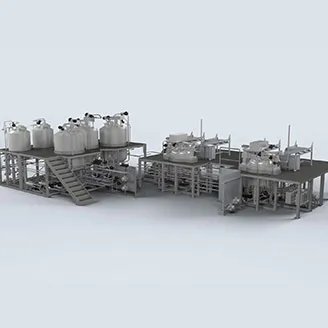

Olsa has extensive knowledge of the complete plasma fractionating process and the high-quality standards it is subject to, having designed, implemented and manufactured several fractionating systems for leading pharmaceutical companies worldwide. For this reason, we developed an innovative design for a thawing vessel implementing a wide range of improvements compared with a traditional unit in relation to all the crucial aspects of the plasma thawing process.

The ThawMX® can have 200% more efficiency than conventional batch thawing systems of the same gross volume and 40% than other continuous thawing systems. Additionally, it guarantees a higher pharmaceutical standard in terms of cleanability and cGMP execution. Its innovative and strategic design allows maximum efficiency and it's functional to melt raw material faster, thus preserving its quality. Also the closed system prevents any risk of exposure to the raw material, improving the equipment safety for operators and also prevents any contamination risk.

Other Biopharma processing applications