Biopharma processing

Vaccines

Overview

Overview

Vaccine manufacturing is a meticulous and highly regulated process playing a pivotal role in safeguarding public health.

It starts with selecting a target antigen, the vaccine’s active component, often a weakened or inactivated form of the pathogen, or genetic material like mRNA. In the case of viral vaccines, the chosen antigen is cultivated in cell cultures or eggs.

Next, the harvested material undergoes purification, inactivation, or genetic modification to create a safe and effective vaccine. Finally, the antigen is combined with various stabilizers, adjuvants, and preservatives to create the final vaccine formulation.

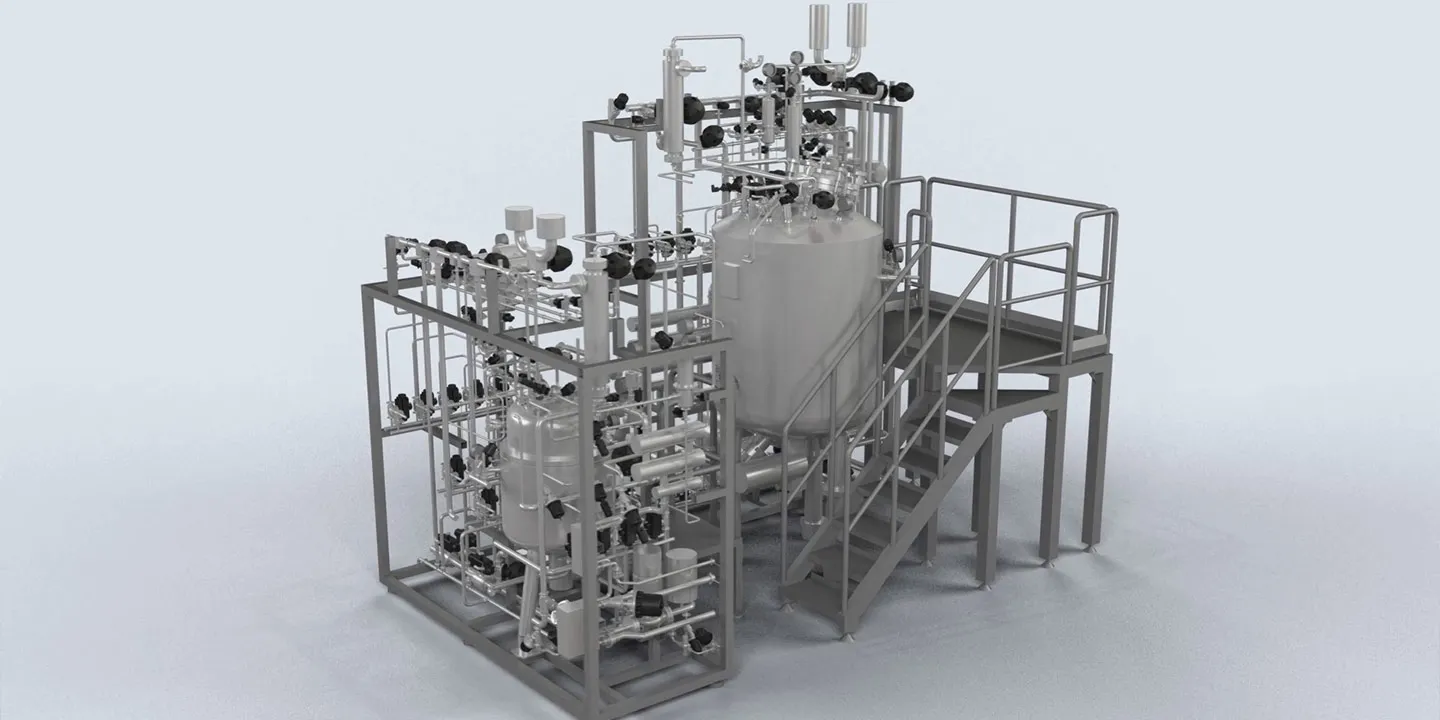

At the heart of the vaccine production process, we find fermenters, also known as bioreactors.

These are crucial particularly in the manufacturing of vaccines based on living organisms, such as viral vaccines and some types of protein-based vaccines. Bioreactors are specialized vessels or tanks designed to facilitate the growth and replication of microorganisms, such as bacteria, yeast, or mammalian cells, under controlled conditions. In the pharmaceutical and biotech industry, they are used for: cell culture, virus propagation, protein expression, fermentation, purification.

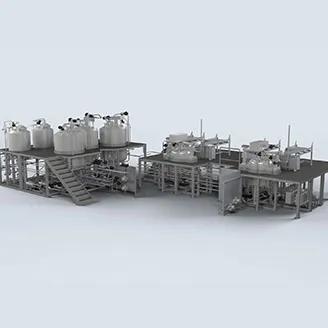

With over seven decades of expertise in bioreactors manufacturing, at Olsa we have achieved unparalleled production efficiency through rigorous process control and advanced automation software management. Our versatile fermenters and bioreactors are available in sizes ranging from 100 liters to 5000 liters (with the possibility to expand this range with customized sizes): this scalability is essential to cater to a wide spectrum of industrial bio-pharmaceutical needs.

Thanks to the synergy with MGA (Masco Group Automation), Olsa can provide a high-level automation package (for example SCADA, DCS) able to handle receipts to guarantee process control and reporting according with highest pharmaceutical and biopharmaceutical standards.

Other Biopharma processing applications