Biopharma processing

Gels and ointments

Overview

Overview

Gels and ointments are pharmaceutical and cosmetic formulations, each with their unique characteristics and uses.

Gels are semi-solid, colloidal systems that consist of a liquid phase trapped in a three-dimensional network of solid particles or gelling agents. They are often transparent or translucent and can be water-based (hydrogels) or oil-based (oleogels). They are commonly used for topical applications, such as skin creams, lotions, and oral products (e.g., toothpaste, antacids). They are also used in pharmaceuticals for drug delivery via the skin or mucous membranes.

Ointments are semi-solid, greasy substances with a high viscosity and lipid-based consistency. They are typically opaque, have a thick texture, and provide a protective barrier on the skin's surface. They are used for various topical applications, including wound care, dermatological treatments, and skincare products.

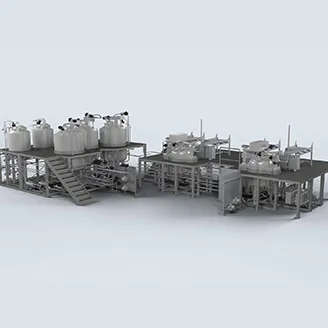

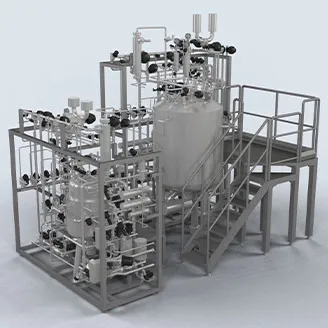

The production of gels and ointments demand careful formulation design, precise manufacturing processes, and strict adherence to quality standards and regulatory guidelines. The equipment used to manufacture these products needs to be able to handle product with high density and high viscosity: the engineering stage in this case is very challenging, because every plant is tailor-made based on the specific physical characteristics of the intermediate and final products. Moreover, temperature control is paramount in this application since it is imperative that the batch maintains a consistent warmth to prevent any potential clogging issues.

The CIP (Clean-In-Place) station holds significant importance as well, due to the difficulty in cleaning cold residues from production, necessitating a specific cleaning cycle.

Olsa holds a global leadership position in the manufacturing of vacuum mixer homogenizers, boasting the capability to perform scale-up and scale-down experiments in its dedicated laboratory for clients, effectively determining the most suitable mixing solution.

Additionally, Olsa's proprietary agitation applications and CIP technology can substantially reduce the overall production cycle time and the water discharge, often halving these essential operational aspects.

Thanks to the synergy with MGA (Masco Group Automation), Olsa can provide an automation package to guarantee process control and related reporting.

Other Biopharma processing applications