Biopharma processing

Fermentation

Overview

Overview

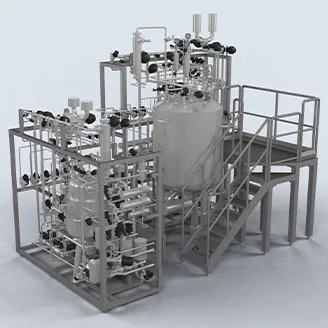

Fermenters are specialized vessels or equipment used for research purposes and in the Biotech and Pharmaceutical industry for the cultivation and growth of microorganisms, such as bacteria, yeast, and fungi under controlled conditions that are ideal for microbial fermentation processes.

Their primary function is biological growth: fermenters provide an environment that allows the microorganisms to thrive and multiply, offering precise control over various critical parameters, including temperature, pH (acidity or alkalinity), agitation (mixing), dissolved oxygen levels, and nutrient supply. These can be adjusted and monitored to create optimal conditions for a various range of microorganisms.

They also can control the aeration and oxygen levels: some microorganisms require oxygen for their metabolic processes, while others are anaerobic and thrive in oxygen-depleted environments. Moreover, they provide a controlled supply of nutrients (e.g., carbon sources, nitrogen sources, minerals) and the nutrient composition can be adjusted as needed during the fermentation process.

Fermenters are used in a wide range of applications, including the production of antibiotics, vaccines, enzymes, biofuels, organic acids, and various biotechnological products. They are also used in research and development to study microbial physiology, genetics, and metabolic pathways.

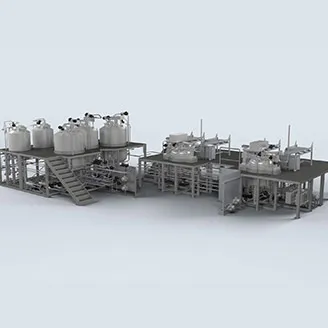

Olsa can provide engineering services that can be conceptual, basic or detailed, along with equipment ranging from pilot units to industrial scale for upstream and downstream multi-stage processes adhering to good manufacturing practice (GMP) standards. The primary objective of these processes is to efficiently produce high-quality biopharmaceutical therapeutic materials that are both pure and bioactive, and in strict accordance with pertinent quality standards and specifications.

Thanks to the synergy with MGA (Masco Group Automation), Olsa can provide a high-level automation package (for example SCADA, DCS) able to handle receipts to guarantee process control and reporting according with highest pharmaceutical and biopharmaceutical standards.

Other Biopharma processing applications